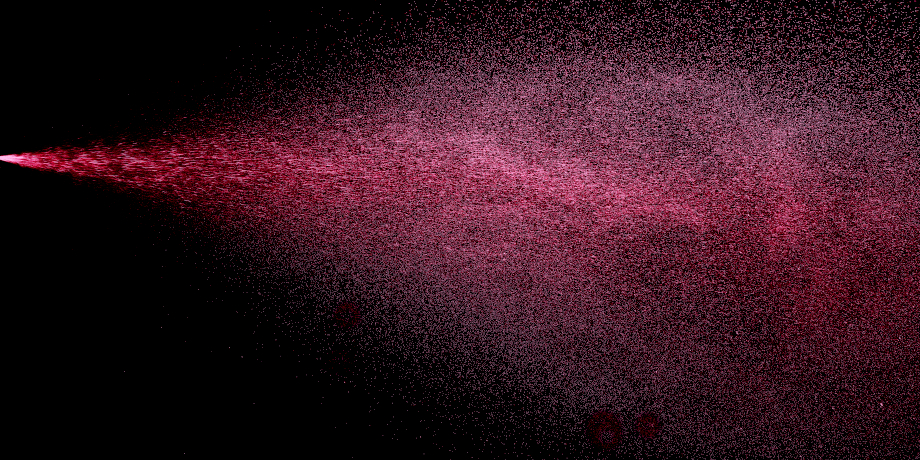

Case study – Design of R&D instrumented spraying testbed for high-viscosity products

Industry : Ingredients

Type : Group

Departments : R&D / New Works

The Client wishes to develop an instrumented spraying R&D tesbed adapted for high-viscosity products and outsources to Rheonis preliminary study, functionnal analysis, design and sourcing.

Expert support mixing science and engineering

We provided to this collaboration our combined scientific and technical knowledge of spraying and related apparatus and our methods for efficient functional analysis and design.

In this study, we performed the following steps in a collaborative manner :

- State of the art of spraying dyes, strenghts and weaknesses with respect to high-viscosity products

- Rheological study of one Client critical product

- Functional analysis of a R&D spraying testbed and recommandations

- Functional SoW with technical options evaluation for Client decision

- Design of instrumented testbed and cost evaluation

- Support for sourcing

Systemic action gauge

Product/process coupling at the heart of design challenges

In this step-by-step collaboration, our role was to provide a robust scientific and technical basis in pre-project phase, in order to help the Client validate its scientific, technical, economical feasability and identify the required level of innovation. A collaborative approach allows to discuss and adjust options and eventually establish an optimised technical SoW.

A unique product/process approach for process design

Understand and modelise product/process couplings

Identify and evaluate technical options on the basis of scientific state-of-the-art

Evaluate overall feasability

Collaborative step-by-step approach with GoNogo

Taylor-made design

Neutrality with respect to providers

You have any project regard complex product/process testbed development ? Feel free to contact us, we will be glad to discuss your subject.

Last Updated on 11 octobre 2021 by Vincent Billot