Case study – Optimization of product/emulsion process by instrumented stirring micro-pilot

Sector: Ingredients

Customer type: Group

Service contact: R&D

The Client wishes to improve the performance of a process emulsification. He entrusts RHEONIS with the R&D study through his original approach to instrumented micro-pilot.

The product/process optimization study

To meet the needs of the project, RHEONIS implemented its combined expertise in mechanical design, instrumental techniques and complex products.

The stages of the study were therefore as follows:

- Development of a micro-driveragitation instrumented adaptable to rheometer

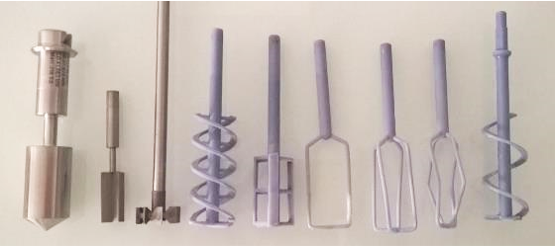

- Design of agitator geometries by 3D printing

- Adaptation, validation and calibration on rheometer

- Study on initial customer formulation of the variability related to process conditions and determination of optimization conditions

- Study of understanding and optimization of formulation factors on final properties

- Conclusions on optimal product/process conditions and operational recommendations

Intervention System Gauge

Bridging R&D and industrialization of complex products

The instrumented micro-pilot approach makes it possible to study, under controlled conditions, with small quantities of material, the conditions for optimizing the product/process couple to achieve the properties desired by the Customer.

The agitation micro-pilot adapted to a rheometer made it possible to study in detail the conditions of preparation, mixing and the kinetics of introducing ingredients to achieve a emulsion to the required properties.

The advantages of the instrumented stirring micro-pilot

Study of influencing factors

Comparison of stirring geometries

Small quantities of product

Quantified data

Controlled conditions

Operational recommendations

Do you have any questions or would you like to discuss your mixing or emulsification projects and issues with us? Do not hesitate to contact us.

Last Updated on February 14, 2022 by Vincent Billot