Case study – Development of an R&D test bench for ink drying in writing

Sector: Inks

Customer type: Group

Service contact: R&I

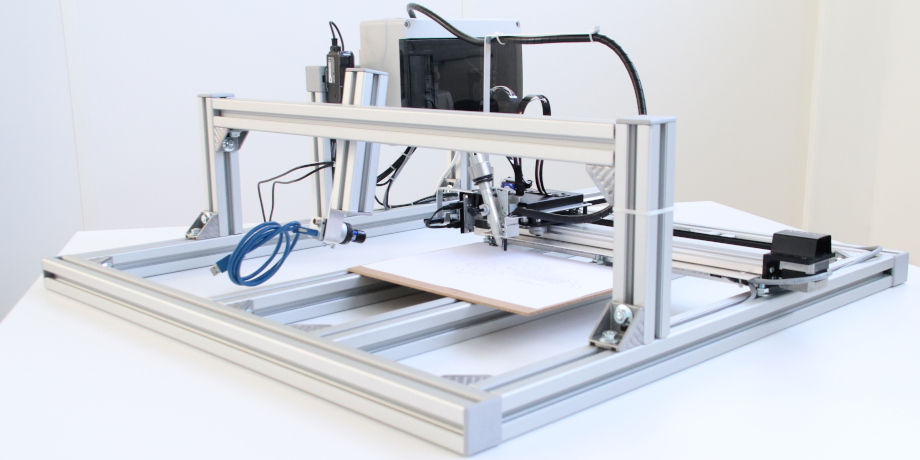

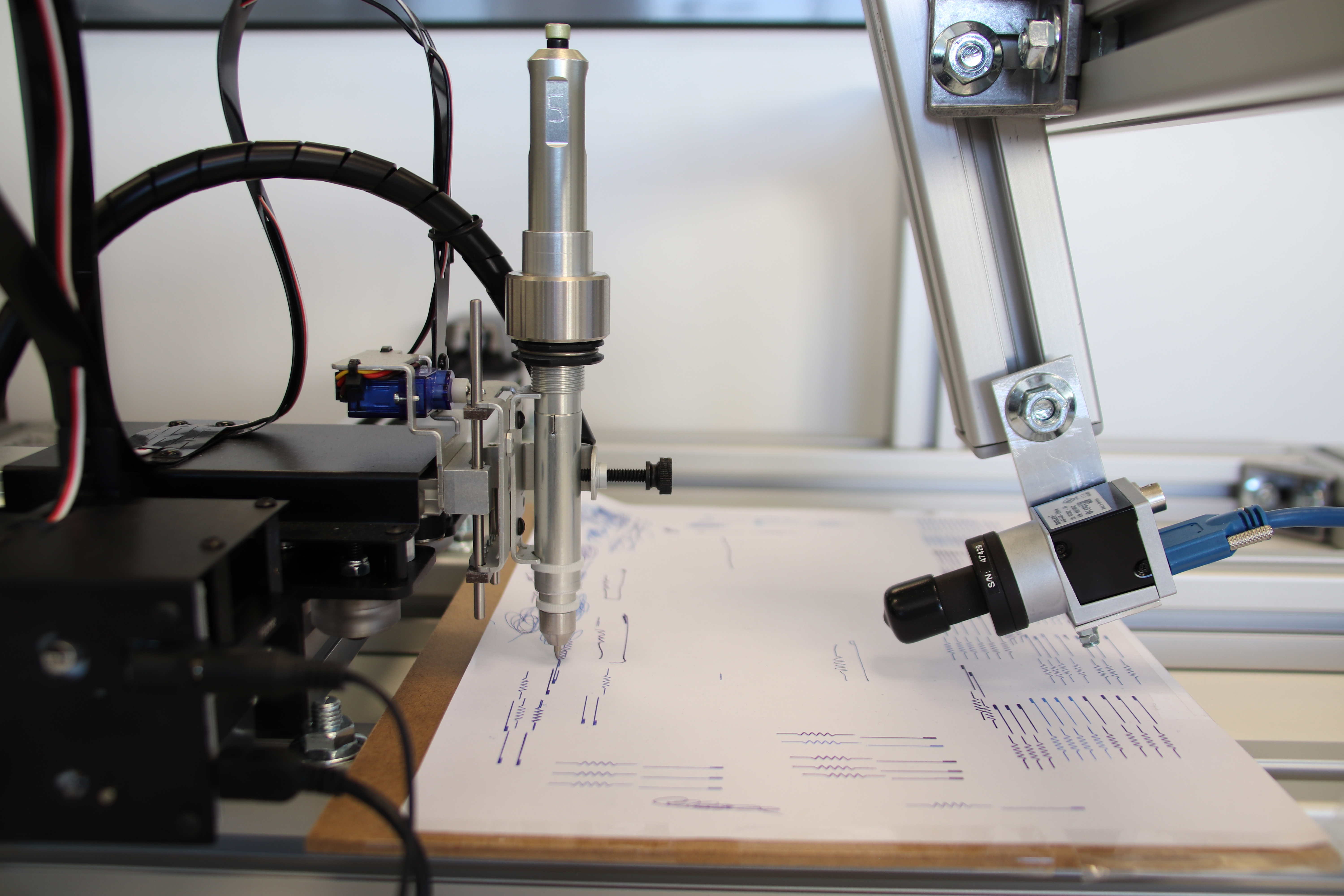

The Customer has in-house test prototypes of its writing systems and in particular the drying of the inks, of which it wishes to improve the precision and convenience of use. He calls on RHEONIS to identify and propose technical options, design, develop and install a dedicated test bench on the Customer site.

A collaborative project at the border between applied research and design engineering

RHEONIS and the Client carried out the project in stages in order to guide the choice of options, evaluate them and gradually remove the risks to guarantee the development of an optimal test bench.

State-of-the-art actions on the impregnation, drying of inks and associated measurement techniques, R&D study of certain specific physical and rheological behavior of inks and their interaction with paper and analysis functional were carried out.

- State of the scientific and technical art

- Instrumental R&D study of ink behavior

- Functional analysis and advice on technical options

- Sourcing and evaluation of sensors

- Costing of a development

- Design & development

- Development of processing routines, edition of an installation guide

- Validation on customer inks

- Installation on customer site and support for getting started

Intervention System Gauge

The contributions of scientific expertise to make instrumental developments more reliable

The approach proposed by RHEONIS makes it possible to gradually refine the specifications according to the contributions of functional analysis, the state of the art, product behavior studies and the sourcing of technological options. The best options can thus be evaluated on the basis of objective criteria before converging on the technical specifications for the final prototype, installed at the Customer's, whose staff is supported for effective handling.

The advantages of the approach for tailor-made prototypes

Collaborative approach for the progressive adjustment of the specifications

Scientific studies to identify and evaluate options

Gradual lifting of risks

Inventiveness on demand

On-site installation and start-up support

Do you have any questions or would you like to discuss your prototype or other projects with us? Do not hesitate to leave us a message and your contact details via the chat, the contact form or contact us directly.

Last Updated on February 14, 2022 by Vincent Billot