Case study – Development of a tool for anticipating the industrial behavior of powder ingredients and for decision support

Agribusiness

Customer type: Group

Service contact: R&D

The Client faces common difficulties related to the behavior of its powders (blockage in silos, caking, hardening, difficult flow, etc.) and wishes to be able to anticipate the behavior of its products under development as well as those of the ingredients it sources. He asks RHEONIS to develop appropriate instrumental methods and integrate them into a decision support tool.

Industrial behavioral R&D for powder decision support

RHEONIS has put its expertise in powders, associated industrial phenomena and instrumental techniques to predict them at the service of the Client.

As part of this large-scale study (on nearly 90 powders), the following actions were carried out:

- Analysis of processes Client, collection of information on the problems encountered and proposal of approaches

- Demonstration of the relevance of behavioral instrumental techniques on some typical cases

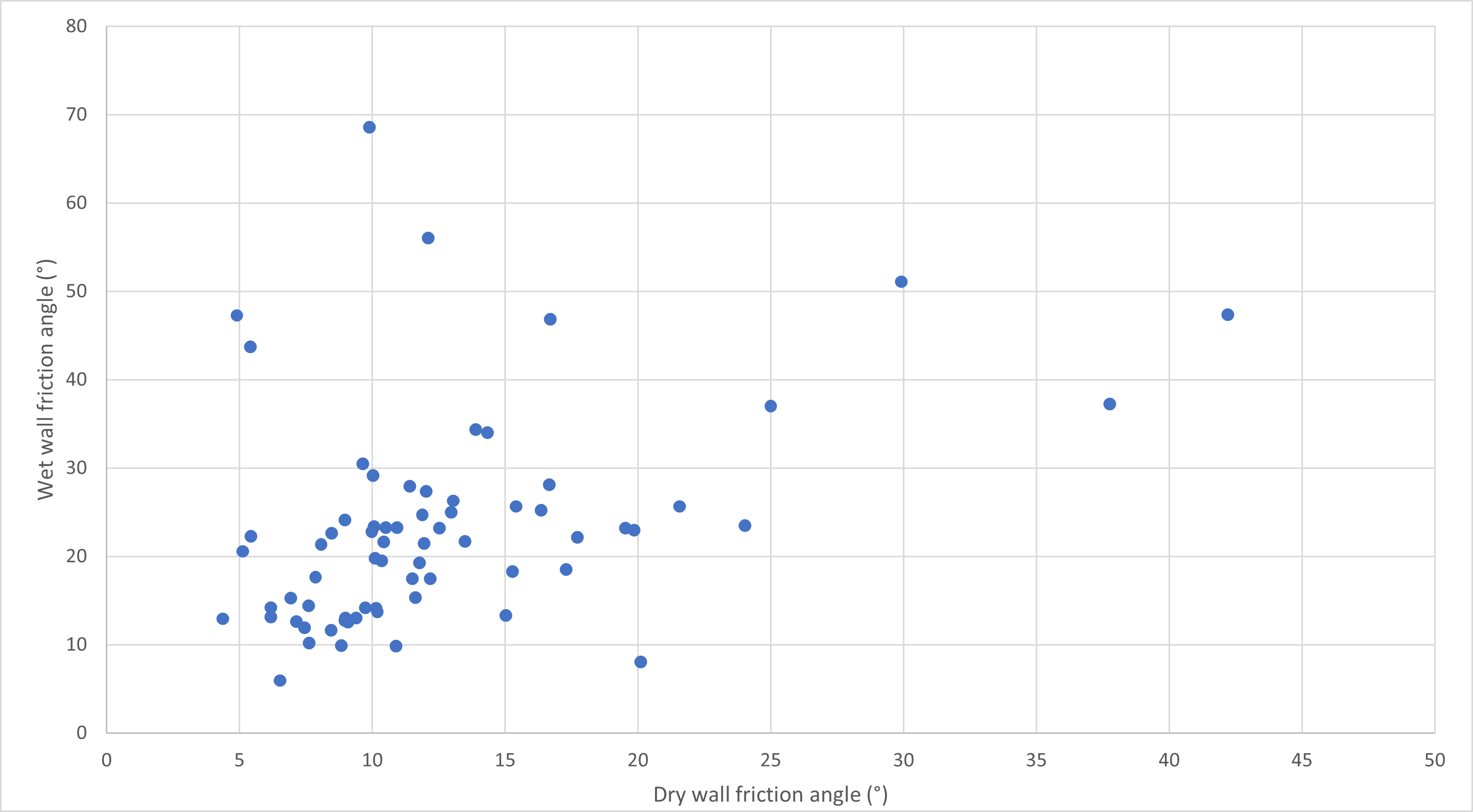

- Systematic study of physical behavior in rheometry powders in dry and wet conditions

- Development of an ad hoc system for monitoring moisture intake and systematic study of products with types of moisture-related issues

- Additional characterization in grain size, tapped density, BET, slope angle, flowability

- Statistical analysis of correlations and conclusions on the parameters of interest

- Development of an excel mapping and decision support tool

Exceeding measurement standards to anticipate powder behavior

Our study has confirmed that most of the usual characterizations of powders have little relevance for discriminating or predicting their industrial behavior and a fortiori the problems likely to be encountered during storage, transportation or implementation.

Behavioral instrumental approaches, resulting from the development of powder rheometry techniques in shear-cell or fluidization cell, make it possible to overcome these limitations. In particular, they make it possible to quantify the sensitivities of powders to humidity and temperature at the origin of a large number of concrete problems and to which the usual characterizations are blind.

On the basis of such an approach of phenomenology and behavioral R&D, the implementation of statistical techniques then makes it possible to extract the parameters best correlated to concrete industrial problems, which macro excel can be used as a real help tool. to the decision.

Our unique approach to powders

Scientific expertise of phenomena (physical, mechanical, rheological, etc.) related to the industrial behavior of powders

Instrumental techniques adapted for the quantification of phenomena under conditions representative of the concrete implementation of powders

Mastery of statistical and modeling techniques to design and enrich decision-making tools on a scientific basis

Experience of industrial processes to recommend optimizations

Do you have any questions or would you like to discuss your powder projects and issues with us? Do not hesitate to contact us.

Last Updated on April 21, 2022 by Vincent Billot