A short history of viscometer and rheometer

I mentioned earlier the confusion surrounding the notion of viscosity, often placing technical exchanges on unstable ground conducive to misunderstanding.

I would like to show, through a brief history, how the various notions relating to viscosity were gradually elaborated over the course of the development of measurement techniques.

The first industrial viscometers

The invention of the term viscometer is attributed to Charles Dollfuss, an industrialist in the textile sector at the time of the first industrial revolution. In 1831, he presented to the bulletin of the industrial society of Mulhouse a note describing a device for comparative measurement of the liquidity index of textile dyes.

It is a container pierced at its bottom which is filled and through which the fluid is allowed to flow by gravity. The measurement of the passage time is translated into a liquidity index. Some will recognize the principle of the viscosity cut, which will be "reinvented" in the 1950s (Ford, Zahn Shell, ASTM, Parlin, Pratt & Lambert, Gottsch, Westinghouse, Demmler, Marsh cuts, etc.).

Efflux viscometer

The rapid development of the industry and the need to make production, supplies and trade more reliable leads manufacturers to set up standardization procedures.

The 1890s will see the appearance of efflux viscometers, intended for the lubricants and petroleum industries, on the same principle as the Dollfuss device: the measurement of the flow time of a product flowing by gravity into a container fitted with a restriction at its base (efflux ). Their essential innovation lies in the control of thermal conditions, the crucial role of which manufacturers have well understood.

Each industrial country sees the birth of its viscometer: Saybolt in the United States, Engler in Germany, Rochwood in England or Barbey in France. Each device has its unit of measurement: the Saybolt second, the Engler degree, etc.

Saybolt viscometer (photo from the National Museum of American History)

Capillary tube viscometer

In parallel with industrialization, the sciences experienced fabulous developments in many fields during the XNUMXth century.è century, notably fluid mechanics, with the pioneering work of Navier, Stokes, Bernoulli, etc.

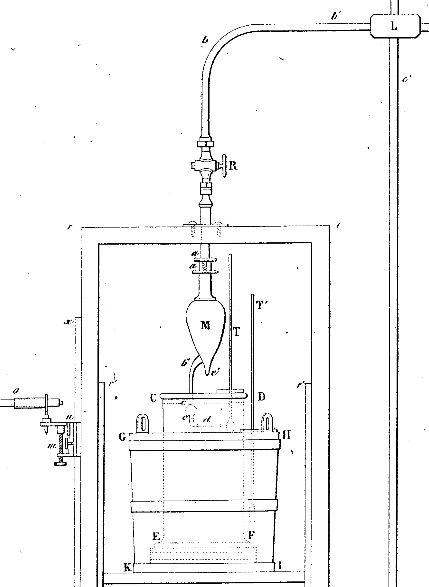

Poiseuille study device (image taken from the reference publication)

From the 1820s, Poiseuille, a physiologist, sought to better understand internal friction in blood capillaries. He developed a sophisticated capillary tube device suitable for determining the relationships between the pressure imposed in the capillaries, their diameter and length, the temperature and the flow rate of the fluid leaving the device. This device will prove to be a powerful tool for investigating fluid flow and testing the laws of hydrodynamics being developed.

Ostwald will develop a simpler capillary tube device in the 1880s, which will be used for the study of industrial fluids, but also by a certain Arrhénius, well known to chemists. Ubbeholde perfected this device in the years 1915.

In practice, in these capillary tube devices, a travel time of the fluid between two marks is measured. Following the work of Poiseuille and Hagen, Hagenbach introduced the notion of viscosity - which would become absolute viscosity- and formalizes the Hagen-Poiseuille law. The scientific community will understand later that the notion of absolute viscosity is not so absolute, and that it must be reserved for a certain category of fluids to which water belongs: fluids anachronistically called Newtonian.

falling ball viscometer

Stokes will develop in the 1840s another type of device associated with the fall of a ball in a fluid, which will allow him to model the friction forces applying to a spherical body in a fluid.

The formulas of Stokes like that of Hagen-Poiseuille bring into play the relationship between absolute viscosity and density, which is called kinematic viscosity - also used to qualify the type of viscosity measured in a viscosity cup or efflux viscometers. Let us insist once again: these notions only make sense in the case of so-called Newtonian fluids - but at the time, no one had yet understood that there were non-Newtonian fluids.

Concentric cylinder viscometers

In the years 1880-1890, while the oil, lubricant and dye industries were equipped with efflux or capillary tube viscometers to control materials, scientists continued to refine their means of study, in particular to gain in precision in the measurement of the viscosity of water and experience the laws of fluid mechanics.

Different devices based on flow between two concentric cylinders will be developed independently by several pioneers (Mallock, Schwedoff, Perry and Couette). Posterity will preserve the name of Quilt viscometer.

Unlike pre-existing devices, the concentric cylinder viscometer makes it possible to control (via one of the cylinders) the stress imposed on the fluid, both in its intensity and in its duration, and to quantify the response of the fluid via the other cylinder. We speak at the time of internal friction, not yet of viscosity.

Schwedoff will conclude as early as 1889 from his work on colloidal gelatin solutions that “viscosity is not constant, as is often believed: it depends on the speed of shearing”. We knew that the absolute viscosity depended on the temperature; we discover that it can depend on the conditions of the implementation of the fluid. The absolute cracks, opening the way to all-out research on so-called colloid systems.

Trouton demonstrates at the beginning of the XNUMXth century the existence of a particular viscosity regime, called extensional, which we will understand later that it is generally linked to the presence of long chains.

Commercial rotational viscometers

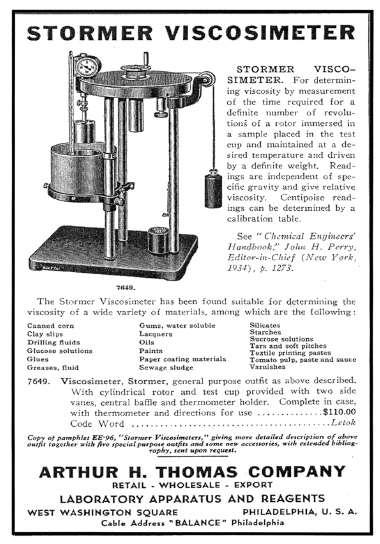

Probably driven by the intensification of the research effort on these devices, a generation of rotational viscometers (Searle, Stormer, Mac Michael) became industrialized in the 1910s. Weight systems made it possible to impose an adjustable constraint on the fluid on one of the cylinders and to determine the resulting shear rate by measuring the rotational speed of the cylinder.

On this principle, but with a simplified geometry, Donald Brookfield's viscometer will see the light of day in 1934. All these devices will be gradually modernized over the course of technological advances in electrical engineering, electronics, digital technology, but the measurement principles will remain the same.

Advertising insert for the Stormer viscometer in the 1930s (from Barnes, reference)

The birth of rheology

The effervescence of several decades of work led in the 1920s to the first models of rheological behavior (Bingham, Ostwald, de Waelde, Hershel, Bulkley). Viscosity changes from absolute to derived quantity – relationship between stress and shear rate.

At the same time, after years of lively scientific debate in the community of chemists, Staudinger demonstrated the existence of polymers, which he called macromolecules. He will also propose the concept of intrinsic viscosity to qualify the residual viscosity of an infinitely dilute polymer solution.

The concepts of viscosity associated with hydrodynamics are far away and the scientific community feels the need for a field of research dedicated to these issues. In 1929, the first "society of rheology was created in the United States, with the aim of studying the flow and deformation of matter, as well as the first “Journal of Rheology”. Reiner makes for the first time the distinction between Newtonian and non-Newtonian fluid [4].

Rheology is becoming a field of research in its own right, with the aim of studying the flow and deformations of matter.

The rheometer: a step further in study capacity

The objects of study are innumerable: clays, rubbers, greases, oils, food products, the first synthetic polymers, etc.

The behavior of polymer systems under shear is complex and different teams are working to refine the rotational devices. Weissenberg and his colleagues will discover the effect - which now bears his name - often observed in agitator manufacturing: from a certain rotational speed, certain products tend to "climb" along the agitator. The phenomenon is associated with viscoelastic effects leading to the appearance of a normal force by relaxation of the shear stress.

The first cone-plane geometries (Ferranti-Sherley) were developed in the 50s, as well as the first in-line viscometer, with a vibrating blade (Bendix).

In the 1970s, a new commercial generation of instruments will see the light of day, with companies such as Rheometrics or Bohlin: the rheometer, capable not only of measuring viscosity properties but also viscoelastic properties.

Other rheometry principles have since been developed, including optical, ultrasonic, spinning, extensional rheometers, techniques coupling rheometry to other measurement principles (microscopy, Raman spectroscopy, etc.).

Progress at the supermarket

This historical overview, obviously not exhaustive, may seem at first sight to illustrate the inexorable march of progress, with its techniques, its scientific concepts and its knowledge which are constantly being improved. The techniques resulting from research lead to commercial solutions, integrated by the industry, which standardizes some of them, while other techniques are developed, and so on.

However, when we turn to the field, the sense of progress is largely at fault. Except in specialist research laboratories or very large accounts with a strong fundamental research culture, modern techniques have not made the old ones obsolete.

All the main families of instrumentation mentioned still exist on the market and are still used (the principle of the most common technique, the Brookfield viscometer, dates from the 1930s; the viscosity cup was "reinvented" in the 1950s ). The majority are subject to regularly updated standards. The scientific names historically associated with these techniques are still in use.

Our little history of viscometer and rheometer looks more like a strange story of accumulation. Accumulation of instrumentations, accumulation of standards, accumulation of concepts.

Accumulation of misunderstandings too. The first of these being the unfortunate confusion between the laws and measurement techniques adapted for Newtonian fluids and the specificities of non-Newtonian fluids, whose sensitivity to the conditions of their implementation makes necessary a more complete understanding of the "product /process” and more suitable measurement practices.

Many generations of industrialists and scientists have advanced the understanding of phenomena and techniques, have defined the perimeters of validity, methods, clarified the limitations and this objective dimension of the progress of knowledge from which the entire industry could benefit for its competitiveness today seems to be sinking into the electronic cobwebs of the archives of scientific literature.

On the shelves of the supermarket measuring the tendency to flow, the labels are incomprehensible to the non-specialist, who ends up forgetting why he wants to measure and his organization what it has to gain from it. Measurement is at the heart of these issues, this measurement that seems self-evident but still struggles to answer our questions.

As global quality pioneer Joseph Juran puts it: “Measurement is the most effective remedy for vagueness and multiple dialects—“Say it in numbers.” This is the first, but not the last, point in the planning process where measurement is critical. Quality planning also requires measurement of product features, process features, process capability, control subjects, and so on. »

References :

Jacobson BO, Rheology and Elastohydrodynamic Lubrication, Elsevier Science, 1942

Poiseuille, JML, Experimental research on the movement of liquids in tubes of very small diameters, Academy of Sciences, Paris, 1846

Tanner IR, Walters K. , Rheology: An historical perspective, Elsevier Science, 1998

Bingham Eugene W., Fluidity and Plasticity, McGraw-Hill, New York, 1922

Ghosal Salil K., Datta Siddhartha, Introduction to Chemical Engineering, Tata McGraw-Hill Education, 1993

Sward GG, Paint testing manual: physical and chemical examination of paints, varnishes, lacquers, and colors, American Society for Testing and Materials, 1972

Barnes, HA & Bell, D.. . Controlled-stress rotational rheometry: An historical review. Korea-Australia rheology journal. 15. 187-196, 2003

Dontula et al., Origins of concentric cylinders viscometry, J. Rheol., 49, 807 (2005)

Reiner M., The General Law of Flow of Matter, J. Rheol. 1, 11 (1929)

Blair GW Scott et al., Rheological methods of control, Analyst, 1949

https://gardco.com/pages/viscosity/vi/ford_history.cfm

https://americanhistory.si.edu/collections/search/object/nmah_2068

Last Updated on September 15, 2022 by Vincent Billot