Case study – Development of predictive methods and decision support tool of powders industrial behavior

Sector: Agrofood

Client: Group

Department: R&D

Our client faces frequent issues with powder handling (blockage in silo, caking, hardening, difficult flow,…) and wishes to improve its tools for the evaluation of candidate ingredients and for the development of its own products. RHEONISis here to develop predictive instrumental methods and integrate them into a decision support tool.

Industrial physical R&D for powders handling

RHEONIS hereby provides its expertise related to powders physics, industrial processes and phenomena and instrumental techniques.

In this large-spectrum study (almost 90 powders), the following tasks have been performed:

- Process analysis, information gathering regarding issues, recommendations for architecture of study

- Demonstration of the potential of physics behavior powder rheometry techniques

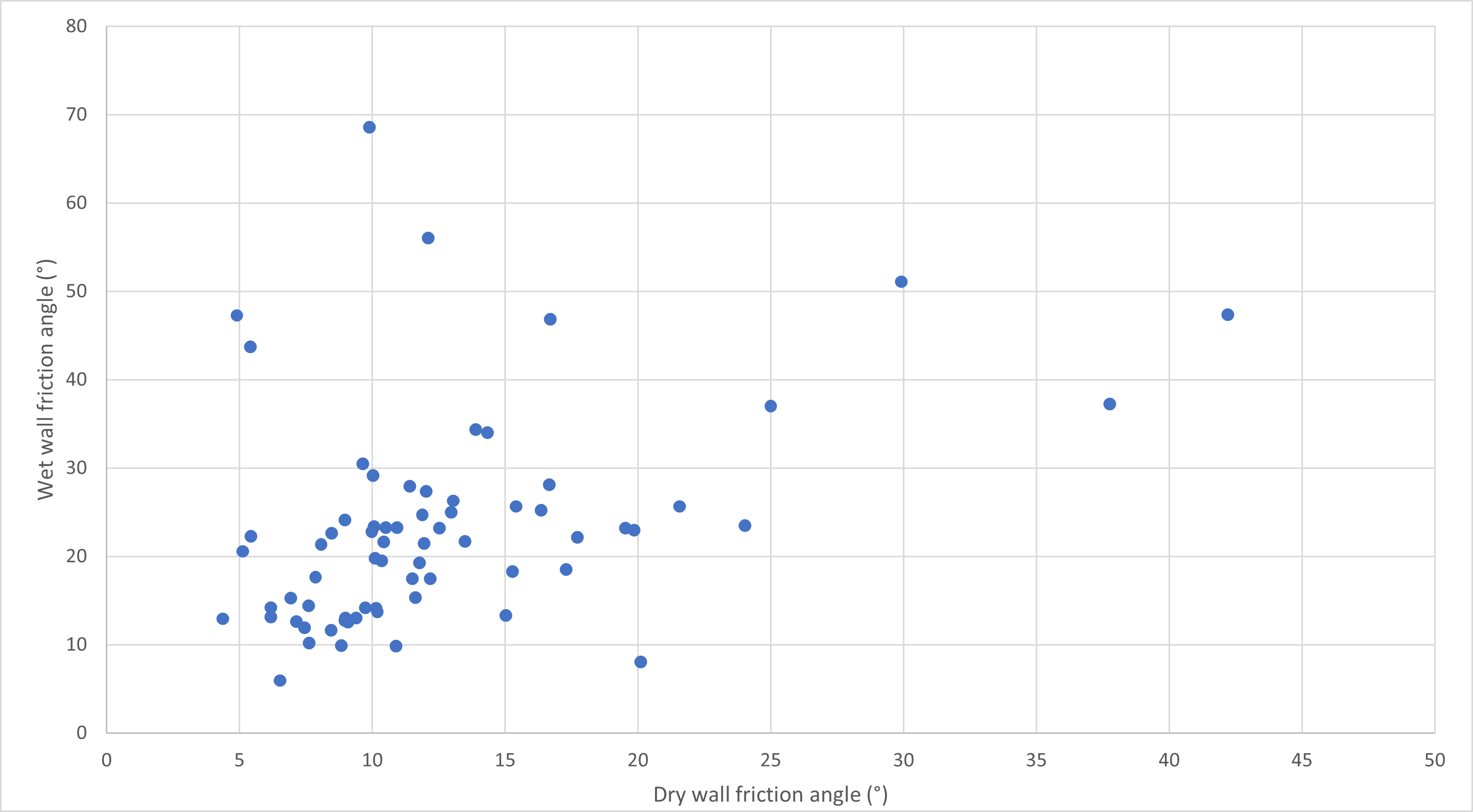

- Systematic study of dry and wet behavior for various parameters of phenomenological interest

- Ad hoc system development for moisture sorption and systematic study of hygrometry effects related powders

- Complementary measurement of standard parameters (granulometry, SEM, tapped-density, BET, angle of repose, floatability)

- Statistical analysis and conclusion on critical parameters and combined quantities of interest

- Cartography and decision-support tool development with excel macro

The need to overcome measurement standards in order to anticipate real-life industrial behavior of powders

Our study confirmed that most of standard powders measurements are of almost null interest for discriminating or predicting industrial behavior and issues regarding handling, processing or storing.

At the contrary, instrumental protocols based on powders rheometry shear-cell and fluidization cell demonstrated the representativity of dynamical parameters with various effects. Hygrometry and thermal effects are strongly related with industrial issues, rendering moisture-sensitity or thermal-sensitivity measurement inevitable for issues anticipation.

Such a phenomenological approach and physics behaviors based R&D allows an efficient use of statistical methods for the extraction of the best correlations with industrial issues. Excel macros are then sufficient for implementing a basical but efficient decision-support tool.

Rheonis' unique approach for powders

Scientific expertise of powders behavior in industrial contexts

Instrumental techniques dedicated to a representative and accurate quantization of powders behaviors

Mastery of statistical techniques and modeling for the design and improvement of decision support tools on scientific basis

Experience of industrial processes for concrete recommendations

For any questions regarding powders projects and industrial issues, feel free to contact us. We will be delighted to discuss your subject.

Last Updated on October 21, 2021 by Vincent Billot