Mixed

Mixing - Agitation Agitation/mixing processes are essential in the vast majority of industries formulating products from liquid, powder or other ingredients. However, when products and/or their ingredients exhibit complex behaviors, formulation, scaling up or production are likely to pose technical challenges that...

Filling Dosage

Filling - Dosing Packaging by filling/dosing is a common process, which nevertheless sometimes poses difficulties for products of the pasty or powdery type. In addition to the dosing operation itself, upstream problems at the level of the feed or the distribution in the channels of the dosing machine may appear. The challenges of filling/dosing, product supply, etc.

Pumping

Pumping The use of pumps is systematic when it comes to conveying material in the pipeline. Depending on the nature of the product and the flow rates targeted, various pump technologies are available: volumetric pumps (with lobes, eccentric rotor), diaphragm, rotary, peristaltic, pigtail, etc. Choosing a pump, crucial technical issue...

Roller coating – squeegee – screen printing – bath

Coating The coating process consists of depositing a coating on a solid or fibrous substrate. There are many coating variants: roller (roll-to-roll), squeegee, screen printing, dipping, calendering,... Whatever the type of coating (paint, varnish, plastisol or other) , the coating brings into play various physical phenomena depending finely on the...

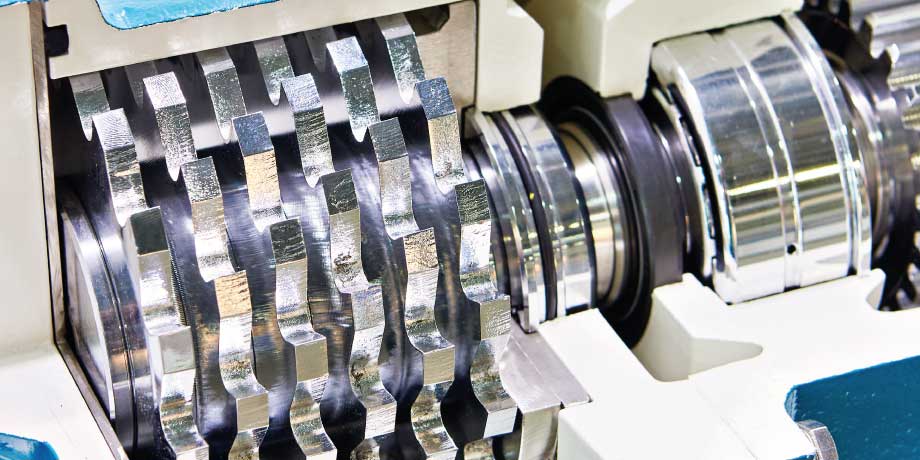

granulation

Powder granulation The powder granulation process qualifies two types of operations depending on the sector: the modification of the collective state of a powder, generally by agglomeration under the effect of a binder (wet granulation), in order to improve the processability of the material, reduce the presence of fines or modify the reactivity of the powder to...