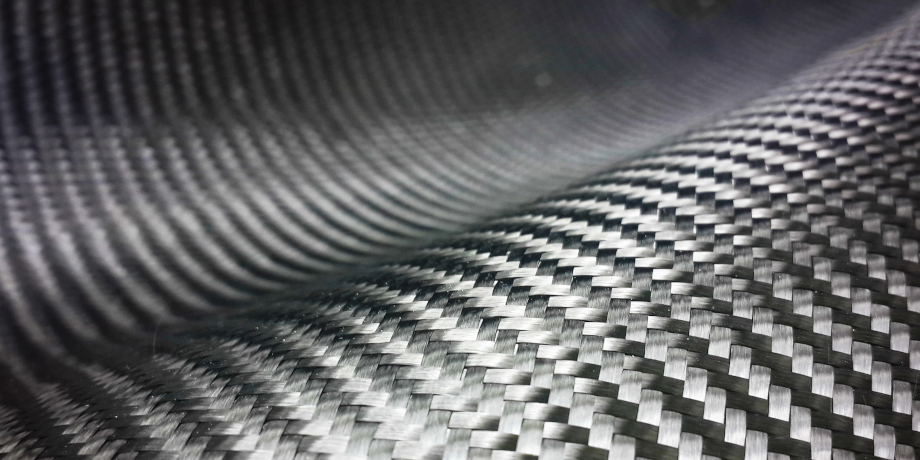

Case study – R&D study of variability in behavior of thermoplastic resins and impregnation on carbon weft

Sector: Composites

Customer type: Group

Service contact: R&D

The Customer observes variability in its process for impregnating resins thermoplastics. He therefore called on RHEONIS to, on the one hand, qualify the variabilities in the thermomechanical behavior of batches of different resins (PEEK, PEI, PPS), and on the other hand, to study their behavior when impregnated on a carbon weft to identify ways of optimization.

Thermomechanical behavior from the powder state to the fluid state then impregnated

In order to carry out this approach, RHEONIS has implemented specific rheometric protocols to control the transition powder-fluid, then the thermomechanical evolution of the resins and finally their impregnation on the Customer's carbon frames.

The main stages of the study:

- Implementation of sample preparation protocol

- Adjustment of rheometric protocols in viscoelastic measurement

- Systematic study of customer resin samples

- Statistical analysis and representation of variability for the parameters of interest

- Opinion on the impact of the ranges of variability observed on the process Client

Intervention System Gauge

Exceed the usual quality controls through specific tests

The study provided the Customer with a statistical view of the variability of resin batches with regard to the properties of interest for its applications. The approach also made it possible to study and interpret favorable compression and thermal conditions for impregnation of PPEK, PEI and PPS resins on a carbon weft. In addition, the Client was able to integrate these techniques into its control practices.

The advantages of rheometric techniques for resins and prepregs

Thermomechanical behavior

Low material consumption

Simulation of implementation conditions

Operational recommendations

Do you have any questions or would you like to discuss your resin, composite, impregnation or other projects and issues with us? Do not hesitate to leave us a message and your contact details via the chat, the contact form or contact us directly.

Last Updated on February 14, 2022 by Vincent Billot