Case study – R&D study of powder granulation in a micro-pilot instrumented on a rheometer

Sector: Chemistry

Customer type: Group

Service contact: R&D

The Customer wishes to adjust the particle size of a powdered product while preserving (or improving) its flowability through a granulation process. He therefore calls on RHEONIS for his methods of instrumented micro-pilot granulation, experimental investigation and characterization of the physical behaviors of powders.

Powder granulation in R&D by micro-pilot instrumented on a rheometer

To carry out this study, RHEONIS implemented its instrumented micro-pilot device for granulation on a rheometer and its techniques of rheometry powders.

The stages of the study were therefore as follows:

- Adjustment of process micro-pilot granulation

- Iterative study of granulation and drying of the customer powder by different binders and concentrations

- Determination of optimal granulation conditions (flow rate, mixed, time, drying) and validation by dry process granulometry and rheometry of powders in shear-cell

- Miscellaneous recommendations for industrialization trials

Increase efficiency in the study of powder granulation

The work carried out made it possible to first validate the feasibility of an effective granulation of the customer's powder by certain binders. The real-time data from the instrumented micro-pilot make it possible to quickly study and efficiently determine the most favorable conditions for reaching the target particle size and preserving the flowability conditions.

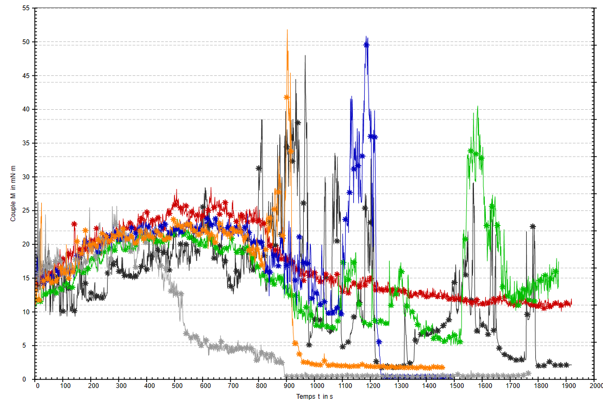

The instrumented granulation micro-pilot approach on a rheometer allows both control of the granulation conditions and real-time monitoring of the torque on the stirrer (directly correlated to the granulation phenomenon, see curve opposite) and a visual monitoring - possibly by camera.

Thus, unlike the usual tests in a granulation pilot, each test gives rise to the production of interpretable quantified data. The analysis of the samples produced by granulometry, tests in powder rheometry or other makes it possible to adjust the granulation conditions to the final properties targeted.

The observation of other phenomena (foaming in particular) adds to the interest of this rapid and effective experimental approach.

The instrumented granulation micro-pilot on a rheometer

Low amount of materials

Real-time monitoring of the granulation phenomenon according to controlled parameters

Quick approach to explore many configurations

Conclusions and operational recommendations

Do you have any questions or would you like to discuss your granulation projects and issues with us? Do not hesitate to contact us.

Last Updated on March 23, 2023 by Vincent Billot