Case study – Development of an instrumented micro-pilot method for liquid foams

Domain : –

Client type : –

Applicant : R&D

Following various requests with foaming issues or interest in enhancing foam’s texture, RHEONIS has developped an instrumented micro-pilot approach upon its rheometry platform in order to produce liquid foams in controlled conditions with the ability to qualify their texture and stability.

Setting up a foam’s instrumental approach based on fluidization cell

RHEONIS applied its expertises in rheometry, experimental physics, special apparatus – fluidization cell mountable on rheometers- and its unique methodology for the development of an instrumented micro-pilot.

In this context, the following actions have been performed :

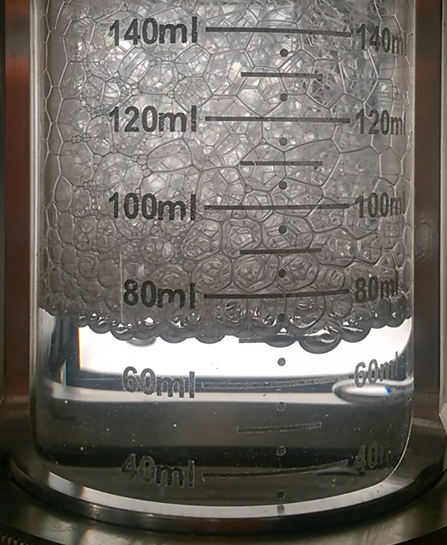

- Preliminary foam production trials in the fluidization cell

- Adjustment of the combined mechanical/optical density tracking

- Production conditions and properties of the foam

- Application note redaction

Produce and qualify liquid foams and theirs influence factors

Foaming is essentially qualified by empirical observations. We have demonstrated in this study the possibility to combine foam’s preparation in controlled conditions (air injection, agitation, ingredients,…) and the qualification of properties of interest (stability, texture, …). Influencing factors of liquid foams become easy to evaluate, investigate and indeed control.

Opening possibilities for foams R&D thanks to the instrumented micro-pilot approach

Determining optimized process conditions for foam production (or foaming avoidance)

Optimizing foam’s texture

Qualifying formulation impact (surfactant, anti-foaming,…)

Understanding product/process influence factors

Last Updated on 10 mars 2021 by Vincent Billot